Dektec Models BEN-Z300 bench lead-free wave

Detailed Product Description

- Traditional panel control. Adopted brand temperature controller, counter, timer and speed controller etc. All these parts provide a stable performance of the machine.

- The sprayer is made in Japan; it provides perfect atomization performance of the flux.

- Sprayer droved by German air cylinder, small noise and long life warranty.

- Forced air convection preheat zone control by temperature controller in PID model.

- The preheat zone will provide enough uniform heat for the PCB.

- Adopt cast iron heater for the solder pot, it’s mounted outside of the solder pot. This new assembling way will prolong the life of the solder pot.

- Dual wave solder. Both wave heights are controlled by transducer. Changing the wave height via adjusting the frequency of power.

- Solder pot is made of SUS316 (standard). Meanwhile we provide Ti material for option.

- Customer can set on and off time of machine weekly.

- Light&Sound alarm for overheating and emergency stop.

- The conveyor system is equipped with overload protection.

| Item |

BEN-Z300 |

| PCB width |

30-300MM |

| Pot Volume |

155kg |

| General power |

10KW |

| Running power |

3.5KW |

Machine Dimension

|

2600(L)*1110(W)*1200(H) |

| Net Weight |

400KG |

| Controlling System |

Panel control |

| Conveyor Motor |

1Ph 220V , 60W |

| Conveyor Speed |

200MM-1500MM/Min |

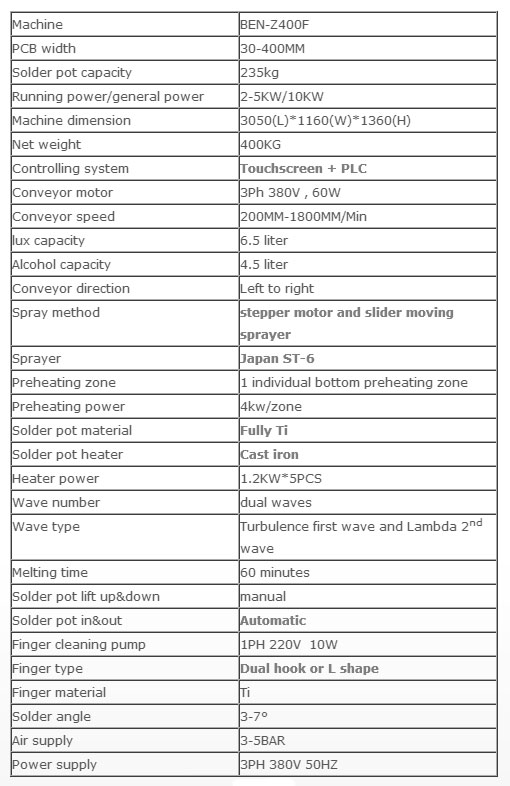

Dektec Models BEN-Z400 bench lead-free wave

- Touch screen and PLC for controlling system make machine very stable. Can save more than 50 groups parameters include temperature information, speed information, spray flux information.

- The sprayer is made in Japan; it provides perfect atomization performance of the flux.

- Sprayer droved by stepper motor and rail/slider guilding rail. This make sprayer moving stable, smooth and long life warranty.

- Forced air convection preheat zone control by PLC in PID model. The preheat zone will provide enough uniform heat for the PCB. The drawer type blower and drawer type heater installation style, make the maintenance very convinent.

- Adopt cast iron heater for the solder pot, it’s mounted outside of the solder pot. This new assembling way will prolong the life of the solder pot.

- Dual wave solder. Both wave heights are controlled by transducer via touch screen. Changing the wave height via adjusting the frequency of power.

- Solder pot is made of TI, 100% no problem for lead-free. We provide 5 years warranty for solder pot itself!!!

- Customer can set on and off time of machine by week timer.

- Light&Sound alarm for overheating and emergency stop.

- The conveyor system is equipped with overload protection.