Description:

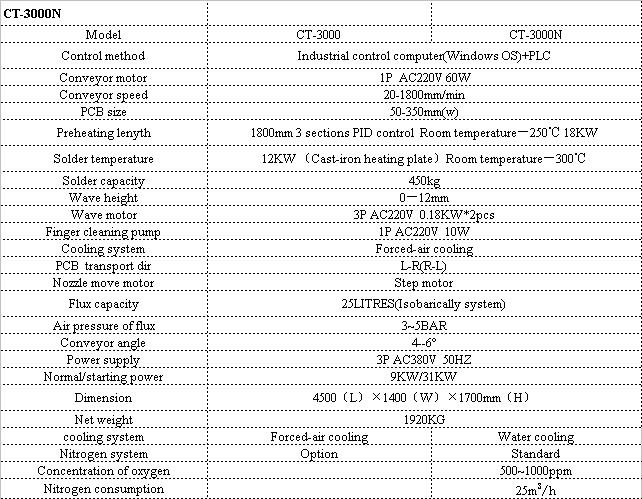

CT-3000/CT-3000N

- Lead-free manufacture procedure and environment friendly design

- Auto synchro input board connected to the equipment ensures a smooth and steady input of board

- Specially made aluminum alloy guides provide hardness and intensity

- Panasonic power conveyance system, infinitely variable adjustment

- Airtight isobarically scaling flux spray system guarantees the invariableness of spray press

- Servo motor and flux spraying head performs a to-and-fro jet, the spraying area is adjusted automatically as the width and speeds of PCB change

- 1800mm lengthening cast aluminium heating board independent PID

- It has the function of heat compensation after pre-heating that makes the temperature of PCB drops least before go into the solder pot

- Tin furnace liner of titanium alloy ,world top technology ,new design of furnace liner elegant appearance, cleaning easily

- Screwy wave screw type jet designed solder SMD component solder parts withent crack

- Fine wave new and advanced technology of horizontal flow little oxygenation quantity streamline flow wave makes solder point perfect

- Soldering system dual wave adopting step less frequency conversion and control wave height independently

- Auto claw cleaning equipment imported high quality mini pump

- Strong cooling system

- The best economical operation

CT-3000/CT-3000N

- The system is controlled digitally production parameter is imputed with numerical values

- Chinese English windows 2000countrolling system control

- PC/PPI protocol is adopted in PC and PLC communication,word stably without system halting

- Manual and automatic rrnning mode optonally

- It is equipped with 3PCB temperature testing points and 3temperature curves can be tested

- Automatically switches on/off according to the date and time set by the user

- All the temperature date speed and temperature curves can be saved transferred and printed

Option

1 Broad PCB welding max 450mm

2 To support the middle parts of mosaic boards

3 The fun blows hot wind to the bottom of PCB

4 Strong cooling system

5 Nitrogen supplied system

6 Source lf nitrogen gas

7 Tin furnace’s automatic lifting and entry system