HIGH-SPEED PRINTING, NO-CLEAN SOLDER PASTE

PRODUCT DESCRIPTION

Multicore MP200 solder pastes have been formulated as no-clean solder pastes for high speed printing and reflow in both air and nitrogen. The products were specifically formulated to have increased reflow process window.

-Suitable for fine pitch, high speed printing up to 200mms-1.

- Extended printer open time and tack-life.

- Prolonged between print abandon time.

- Essentially colorless residues

- Soft residues make pin testing easier eliminating any need for cleaning.

- Resistant to both hot and cold slump.

- 63S4 alloy for Anti-Tombstoning

-ROL0 TO ANSI/J-STD-004

63S4 ANTI-TOMBSTONING ALLOY

Where tombstoning is a particular process problem then 63S4 alloy may offer an instant solution. 63S4 alloy is a blend of different melting point alloys with a special mix of solder particle sizes. This modification extends the melting range of the alloy hence reducing the possibility that one solder deposit at a component termination can fully reflow before the other.

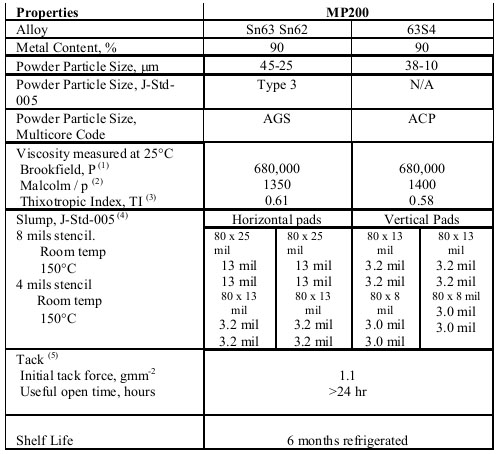

TYPICAL PROPERTIES

(1) Measured at 25°C, TF spindle at 5rpm after 2 minutes (typical)

(2) Measured at 25°C, and a shear rate of 6s-1 (typical)

(3) TI = log (viscosity at 1.8s-1/Viscosity at18s-1)

(4) Slump data are expressed as the minimum spacing between pads of the size shown that does not allow bridging

(5) Tack data are derived from comparative laboratory tests and do not necessarily relate directly to a particular user’s conditions

SOLDER POWDER

Careful control of the atomisation process for production of solder powders for MP200 solder pastes ensures that the solder powder is produced to a level that exceeds IPC/J-STD006 & EN29453 requirements for size distribution, impurities & oxide levels. Minimum order requirements may apply to certain alloys and powder particle sizes.