NO CLEAN RMA SOLDER CREAMS

Multicore RM92 solder creams have been formulated as No Clean RMA type products showing superior resistance to preheat slump during reflow processes.

- Screen printing and stencilling grades available

- Grades suitable for fine pitch applications available

- Excellent resistance to preheat slump

- Good tack performance and wetting

- Residues may be left uncleaned

PRODUCT RANGE

Multicore RM92 solder creams may be supplied with solder powder made from most solder alloys in the Multicore Product Range. The most common alloys used are Sn60, Sn62 and Sn63 conforming to the purity requirements of J-STD-006 and EN 29453. Minimum order requirements may apply to certain alloys and powder particle sizes.

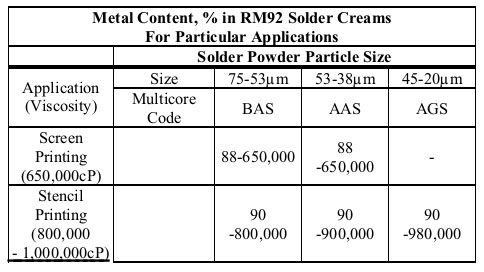

A wide range of metal contents and solder powder particle size distributions may be ordered but most applications will be served by the following recommended products:

For dispensing applications, the equivalent Multicore RM89 solder creams are recommended.

If clear residues are preferred, the user should evaluate the No-Clean range. Customers wishing to print at high speed should consider Multicore RP10 solder creams.

TECHNICAL SPECIFICATIONS

Solder Powder: The solder powder for Multicore RM92 solder creams is produced by atomising alloys conforming to the purity requirements of J-STD-006, EN 29453 or other national and international standards where relevant.

Careful control of production processes ensures that the solder powder is at least 97% spherical (aspect ratio < 1.5) and contains less than the minimum level of contaminants that would adversely affect solder cream performance. A typical maximum oxide contamination level of 80 ppm (expressed as oxygen in the solder) is regularly achieved or bettered.